Improve Current Processes and Reduce Environmental Impact

The Challenge:

A paint manufacturer aims to develop a high-performance, low-VOC (Volatile Organic Compounds) paint

for industrial applications. The current formulation, while exhibiting

excellent adhesion and durability, contains VOCs that exceed increasingly

stringent environmental regulations. The challenge is to optimize the paint

formulation to significantly reduce VOC content without compromising its critical

performance characteristics, such as adhesion, durability, and drying time.

Traditional methods of trial-and-error reformulation are time-consuming and

expensive, often leading to suboptimal results.

The Process:

The manufacturer provided a small existing experimental dataset on various paint

formulations, including VOC content, adhesion, durability, and drying time.

The Find What Matter's AI platform was used to build a model that captured the

complex non-linear multidimensional relationships between formulation variables

(e.g., solvent types, resin ratios, additives) and performance outcomes.

FWM AI optimization was employed to explore the formulation space

and propose new experiments with reduced VOC content.

FWM iteratively suggested formulations, balancing the competing

objectives of low VOCs and high performance.

The paint manufacturer's chemists reviewed and validated the proposed formulations, helping to provide expert input to ensure feasibility and safety.

Each round of experiments was used to update the FWM model,

improving the accuracy of subsequent recommendations.

The AI-driven optimization process identified key formulation variables that significantly

influenced VOC emissions and performance. Targeted experiments were conducted to fine-tune

these variables, leading to a final formulation that met the desired criteria.

Rigorous testing was performed to validate the performance of the new low-VOC paint,

ensuring it met industry standards.

The Outcome:

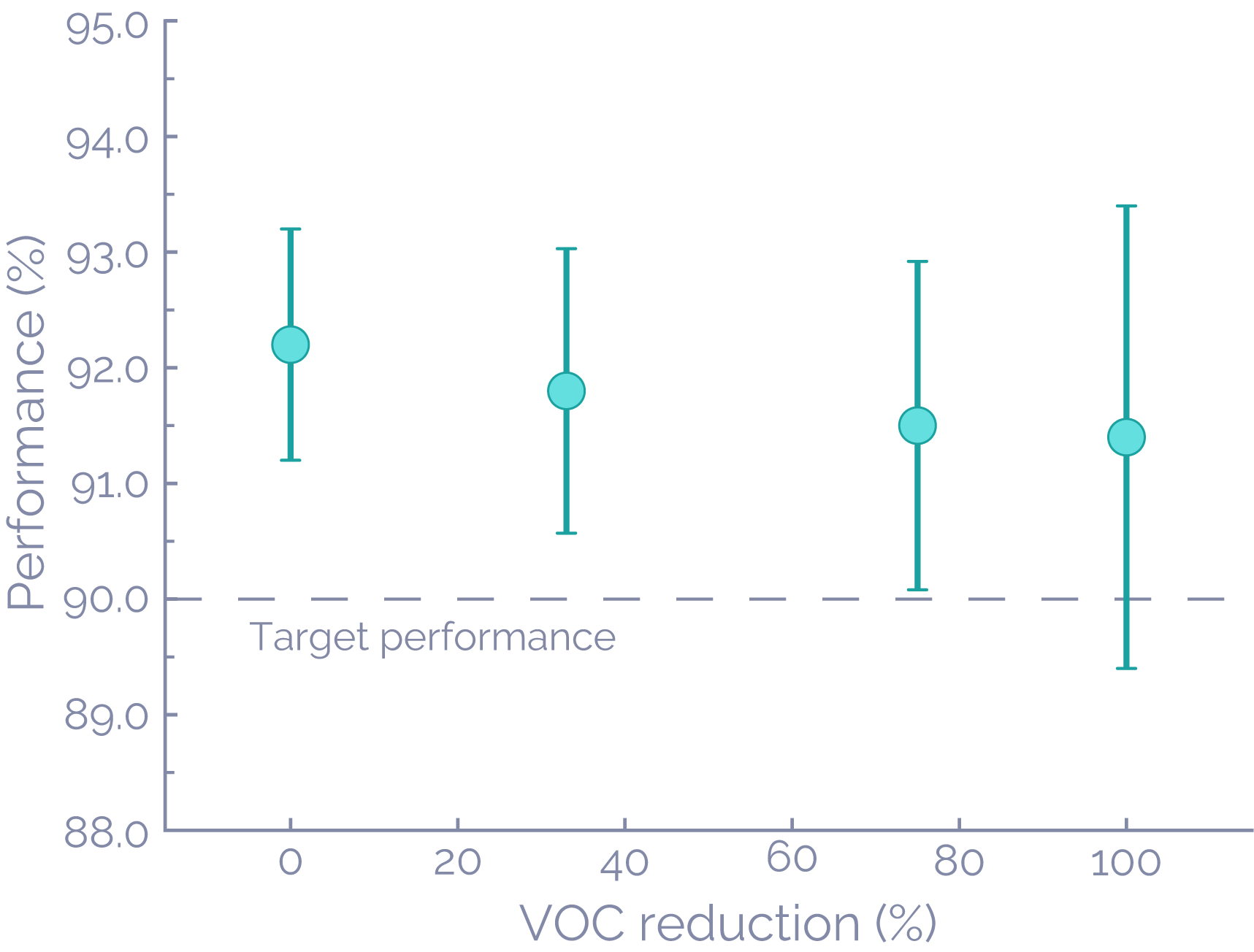

Using Find What Matter's AI-driven optimization, the paint manufacturer successfully

developed a new low-VOC paint formulation that met all performance requirements while

significantly reducing VOC emissions. The resulting paint exhibited comparable adhesion

and durability compared to the original high-VOC formulation.

Summary:

This use case demonstrates how Find What Matters AI-driven optimization can effectively

address the challenge of developing high-performance, low-VOC paint formulations. By

combining experimental data, expert knowledge, and FWM AI-driven process

optimizatoin, the paint manufacturer was able to significantly reduce VOC emissions without

sacrificing critical performance characteristics. The optimization process not only accelerated

the development cycle but also yielded novel product that met both environmental and performance

requirements. This allowed the company to stay ahead of regulatory requirements and provide a

superior product to its consumers.