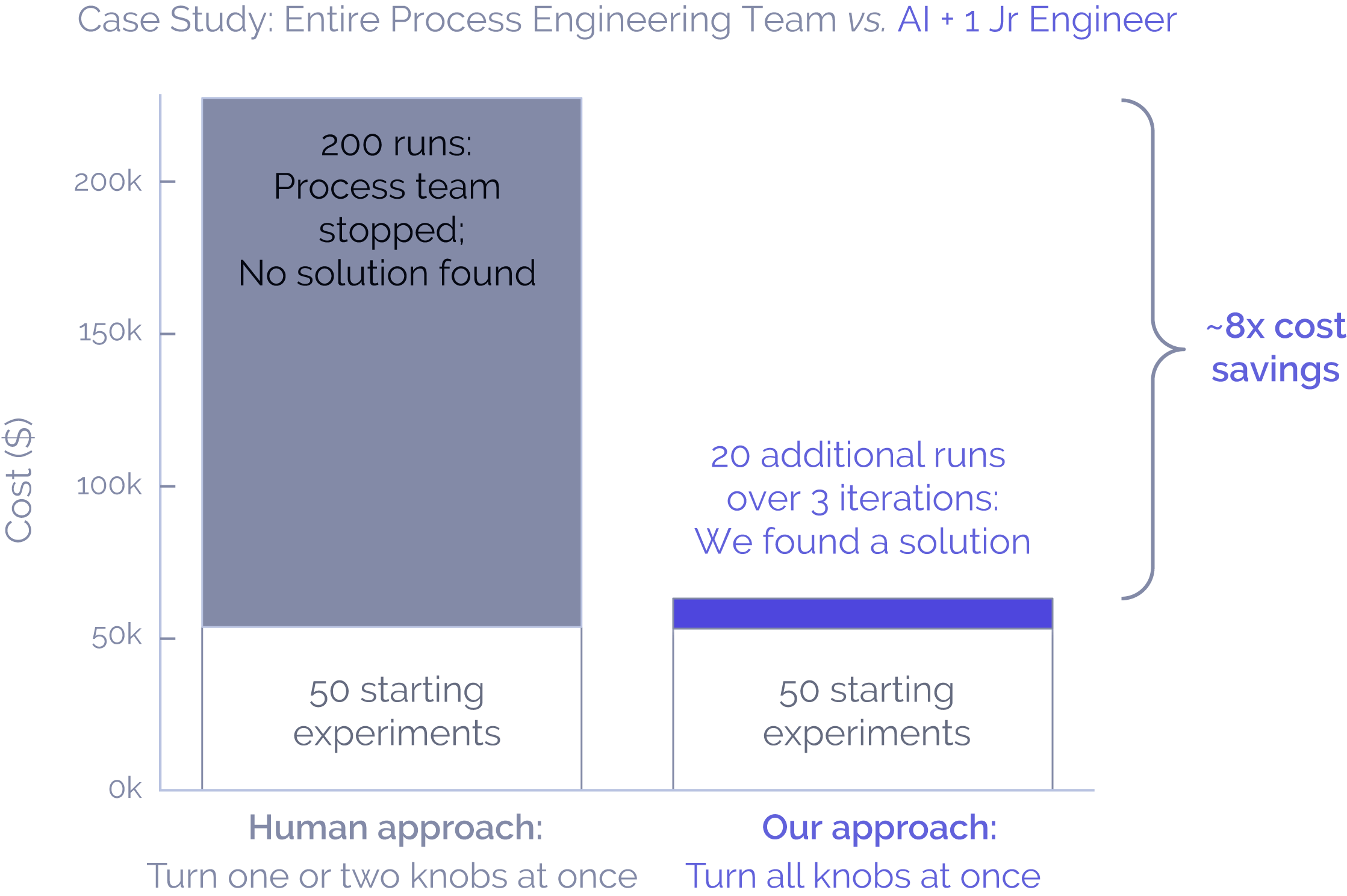

The Challenge:

A biotechnology manufacturer needs to develop a cost-effective fermentation

process for directed evolution of a particular bacteria. The process is

multifaceted, requiring optimization of the growth medium and bioreactor

fermentation parameters. Optimizing this process (at low cost) allows the

company to capture significant market share.

The Process:

- Initial Design of Experiment:

To optimize the fermentation process, we first identified the key input

parameters. These included factors such as the type and concentration of

carbon and nitrogen sources, temperature, pH, dissolved oxygen, and agitation.

We used historical data and a space-filling design to efficiently sample the

input space. In this example, the engineering team provided 50 initial experiments.

-

Find What Matters Takes Over:

We then used the FWM AI-driven optimization to define desired targets

and propose new experiments with input parameter settings likely to lead to a low-cost fermentation process.

-

Iterations:

Proposed experiments were vetted by the bioengineers and then conducted. Our

algorithm was then updated with the new experimental data. This process was repeated

three times until a winning solution was discovered.

The Benefits:

- Reduced Development Costs: We developed a fermentation

process meeting yield targets and production costs.

-

Faster Return on Investment:

The customer's engineering team ultimately stopped after 250 unsuccessful attempts to find a winning process. After implementing FWM, the customer found a solution that the process team had failed to achieve.