Improve Hardware Capabilities

The Challenge:

A common process flow for synthesizing high-quality graphene involves a chemical

vapor deposition (CVD) step (i.e., growing a single-atom-thick carbon layer on a

metal substrate) followed by a transfer step (i.e., detaching the graphene from the

substrate and placing it onto a target surface). The CVD step begins by heating a metal

catalyst (i.e., typically copper or nickel) in a furnace and then introducing a

carbon-containing gas (i.e., methane or acetylene), inducing a surface reaction that

forms the graphene layer. The result of a perfectly ideal CVD / transfer process yields

a continuous, defect-free graphene film (i.e., maximizes the material's structural integrity)

while minimizing damage or contamination during transfer, yielding a pristine interface

(i.e., structures with minimal interfacial defects). The two objectives of achieving high

structural integrity while minimizing transfer-induced defects are in tension, as the same

chemical environment that facilitates graphene growth can also introduce impurities or

structural imperfections, and the necessary transfer process can introduce tears or

contamination.

The Process:

After training an initial model with scientist expertise and experimental data, the

first set of recommendations suggested lower CVD growth temperatures and higher gas

flow rates. Though these showed improvement, the furnace's standard heating rate and

gas delivery system couldn't achieve the parameters proposed by FWM. Consequently,

scientists adjusted the FWM recommendations to be feasible with the current equipment.

This analysis highlighted hardware limitations, prompting the replacement of standard

heating elements with rapid thermal annealing (RTA) and the installation of mass flow

controllers (MFCs) for precise gas delivery before the second iteration.

A second batch of experiments was then recommended, leveraging the extended capabilities

of the new hardware, resulting in successful realization of the specification for low

defect density (high structural integrity) without any compromise on the transfer-induced

defects. Evaluation of the second batch of experiments revealed that the improvements in

the second iteration hinged upon a more controlled cooling profile during CVD, motivating

engineers to redesign the furnace chamber to enable a rapid and uniform cooling process

while still meeting the requirement of a precise gas flow.

After installing the new cooling system and retraining the model, the third batch of

optimized experiments ultimately achieved both of the target specifications.

The Outcome:

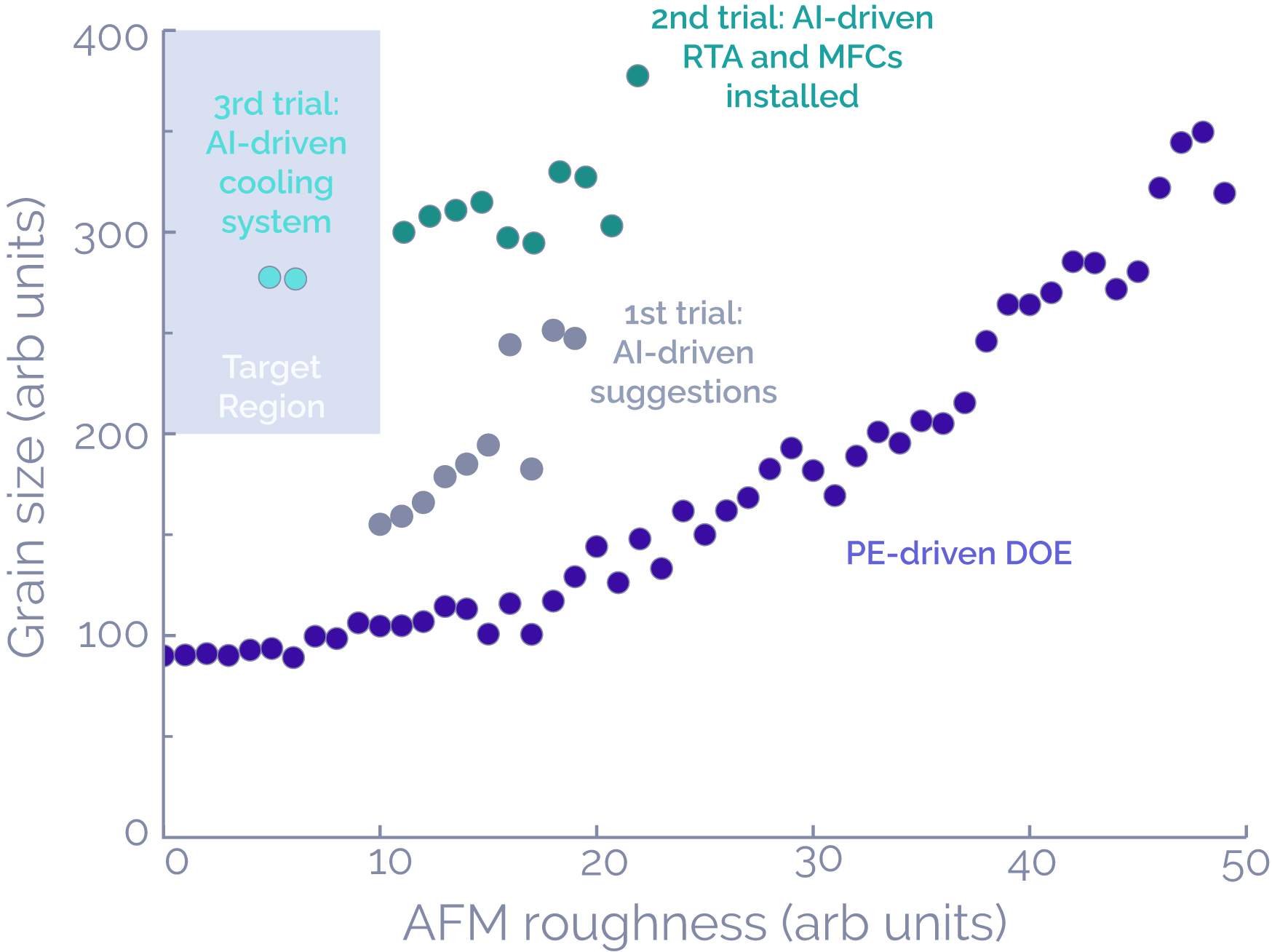

A representative optimization trajectory is depicted in the plot above, wherein

Find What Matters successfully co-optimized these competing objectives in a few

iterations and with the involvement of an informed materials scientist in the loop.

Summary:

This trajectory illustrates some key features of how AI-based recommendation

routines can assist an informed materials scientist towards their process

optimization objectives. While AI-based engines may recommend process conditions

that immediately result in achieving target specifications, these same engines can

offer guidance even when those objectives are not immediately attainable. In the above

example, the original hardware configuration explicitly precluded hitting the target

specifications; however, scientists were able to leverage a machine learning model (that

had learned the latent relationships between input temperature, gas flows, cooling rates

and output defect density / transfer defects) to deduce which hardware adjustments were

necessary (in this case, switching to RTA elements, mass flow controllers, and redesigning

the cooling system) in order to iteratively progress towards the objectives. AI

recommendation engines excel at identifying and prioritizing important combinations of

experimental control parameters, freeing up the domain expert to exercise their creativity

in realizing those optimized outcomes. By identifying hardware limitations and suggesting

modifications, the optimization process enabled the achievement of both target

specifications, which wasn't possible with the original hardware. The upgraded hardware

allowed for a more efficient and effective graphene synthesis and transfer process. The FWM

optimization process pushed for innovative solutions by encouraging hardware modifications

beyond simply adjusting process parameters.